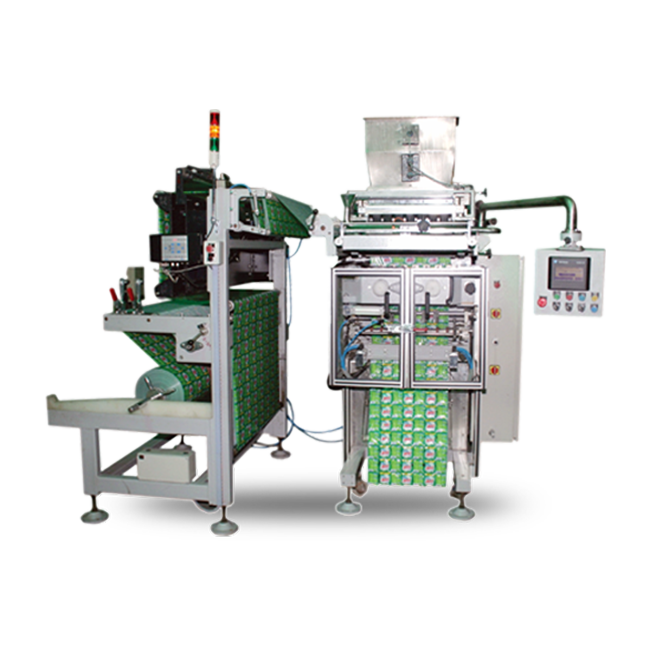

For Free Flowing Products

- Sealers are both end supported

- End roll detection synchronized with PLC & Filling

- Provision for batch cutting & counting

- Temperature Control and Heater Failure Indication is through PLC hence, eliminating the need for temperature controller

- Paper break detection sensor

- Joint detection sensor (optional)

- Hopper level controller

SPECIFICATIONS

| Sealing Style | 4 Side Seal |

| Speed | 70 Strokes / minute maximum (Depends upon the type of product & quantity to be filled) |

| No. of Tracks | Depends upon the width of the pouch |

| Laminate Specification | Length 2000 mm Roll Dia – 600mm. max. Reel Core I.D.- 150/76 mm |

| Packing Material | Laminates with one side heat sealable |

| Filling Capacity | 1gm-300gm |

| Product To Be Packed | Any type of free flowing powder |

| Sealing Drives | Mechanical – Cam driven with individual sealing jaw setting |

| Filling Mechanism | Slide Filler |

| Perforation and Cutting | As per customer requirement |

| Laminate Roll Unwind | Motor driven – Bonfiglioli Geared Motor. |

| Laminate Draw Off System | PLC based Servo Driven. |

| Control | Through Touch Screen Panel (HMI) |

| Laminate Tracking System | E+L web aligner – Digital. |

| Main Control Panel | Air cooled panel – BCH make or Rittal |

| Contact Parts | SS 316 L |

| Indirect Contact Parts | SS 304 / 316 |

| Batch Cutting | Can be programmed through PLC |

| Mat Format | In built feature of the Machine. |

| Electrical Spec. | Main Motor – 2.2 KW, 3 Phase, 415 V Connected load – 14 Kw. Consumption – 11 Kw. PLC controlled Operations RTD module with PLC for Temperature controllers |

| Layout Dimensions | Length -3200 mm Width – 2600 mm Height – 2100 mm |

| Machine Weight | Net Weight – 3500 kgs. Gross weight – 4000 kgs. |

| Compressed Air | Operating Pressure – 5 Bar. Consumption – 3 CFM. |

| Pneumatics | FESTO or equivalent. |

| Machine Efficiency | 90%* |

| Scrap Rate | Less than 2%* |

| Machine Colour | Shell Grey – Powder coated. |

| Weight Variation | Within +/- 1%** of the filled quantity |